Ngophuhliso loshishino, ukusetyenziswa komatshini wokwenza umbhobho wensimbi engenasici kuya kuxhaphaka ngakumbi, nokuba ukugcinwa kwesixhobo ngasinye kwindawo, kuchaphazela ngokuthe ngqo umgangatho wemveliso, kunye nobomi benkonzo yezixhobo. Ukugcinwa kakuhle kunokuphucula ukhuseleko kunye nokuzinza, ukuqinisekisa ukuba ukuveliswa komgangatho ophezulu wokugqitywa. Kodwa ukuba awuqhelananga nomatshini wetyhubhu yokulawula intsimbi engenasici, usenokungakwazi ukuqalisa ukulungiswa. Emva koko olandelayo uza kwazisa umsebenzi wokulondoloza kumatshini wokulawula umbhobho wokuhlobisa insimbi engenasici, ndiyathemba ukuba unokukunceda.

1. Ukucwangciswa kombane kweyunithi ye-welding yensimbi engenasici ithatha ukulawulwa kwesantya sokuguqulwa kwamaza.

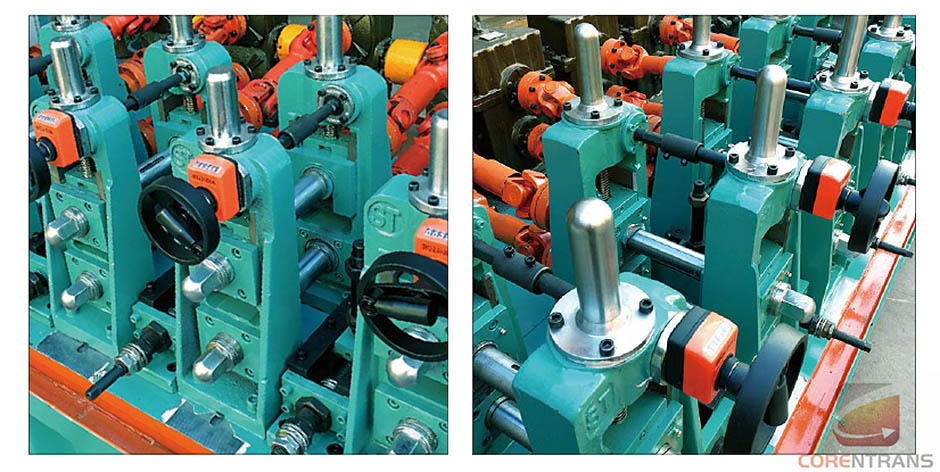

2. Isakhelo esithe tye isakhelo esijikelezayo, ukujikeleza kwayo kwibhokisi ye-turbo-worm kunye ne-coupler, okwenza iyunithi ibe lula ngakumbi ukuba isebenze kwaye izinzile ngakumbi.

3. Umatshini wokubumba kunye nobukhulu buqhutywa yimoto enye enesakhiwo esincinci. Ukugcinwa kulula kakhulu, kwaye kulula ukusebenza.

4. Ukuseta i-oil pump yomatshini wokulinganisa wangaphakathi, nangona kukho isihluzo sangaphakathi, abathengi basafuna ukwenza umsebenzi wokucoca rhoqo ukuze baqinisekise ukuba ipompo yeoli ayiyi kuvalwa. I-air passage ye-oxygen sensor kufuneka iphinde ihlambuluke rhoqo ukukhusela ioli eninzi kwi-clogging kunye nesiphaluka esifutshane.

5. Isakhelo sokulayishwa sithatha i-rotatable parallel four-link cantilever double reel mechanism, enokuthi ibe nenxeba ngexesha lokusebenza kweyunithi, enokunciphisa ixesha lokulungiselela kwaye yenza ukuba iyunithi iveliswe ngokuqhubekayo ngaphandle kwenaliti yokugoba.

6. Isikhundla esithe nkqo sinokulungiswa ngokuthe tye okanye ngabanye kwisiseko, kwaye sinokulungiswa ngokuthe nkqo.

7. I-centerline ye-spindle ye-grinders yokuqala ye-welding kunye ne-rolling centerline inokulungelelaniswa, kwaye i-weld seam iphuculwe ukusuka kumacala omabini ahamba phambili. Umbindi welo mva liziko le-welder, kwaye i-weld seam iphantsi ngokuthe ngqo kwi-angle ye-90 degrees ukuya kumgca we-rolling center, okwenza umphumo wokupholisa ube ngcono.

8. isakhelo esithe tyaba sisecaleni lendlela-mbini ngaphandle kwesibiyeli sesakhelo sokuhlalutya, xa imfuneko yokutshintsha i-velvet, ikhulule i-bolts yokulungisa izibiyeli zangaphandle, ukucutha kwesakhelo kumacala omabini ngokulandelanayo, ukulungiswa okuguquguqukayo.

Oku ngasentla malunga nomsebenzi wokulondoloza onxulumene nensimbi engenasici yokulawula umatshini wokulawula umbhobho, ithemba unokukunceda.

Ixesha lokuposa: Dec-16-2020