Iindawo ezisecaleni kunye nezinto ezisetyenziswayo

Sibonelela ngazo zonke iintlobo zezixhobo, iishafti, iimotor, iibhokisi zothumelo, iindawo zombane, iintlobo ngeentlobo zezixhobo ezifumanekayo, kunye neendawo ezisetyenzisiweyo; nceda usazise ngemodeli okanye imifanekiso yemveliso. Sinikezela ngezona zincedisi kunye neenkonzo ezifanelekileyo.

Tube Mill Accessories

| Ibha ye-magnetic ferrite | Ityhubhu yeFiberglass |

| Ngaphandle isixhobo sokukrwela kunye nesuntswana lemela | Saw blade |

| Ngaphakathi isixhobo sokukrwela kunye nesuntswana lemela | Ikhoyili yokungeniswa |

| Inkqubo yokugquma iZinc | |

Izixhobo zifuna ukucocwa kunye nokugcinwa, kwaye izincedisi kufuneka zitshintshwe ngexesha.

KubaI-ERW Tube MillUkugcinwa koomatshini kunye nokusebenza:

a.Kanye ngeveki ukujonga i-emulsion kunye nesikhululo sokupholisa ukwenza amanzi kunye neoli.

b.Nika ingqalelo kwi-lubrication yokongeza iibheringi, ibhokisi yokunciphisa isantya segiya kunye ne-rack. Ukuba i-lubrication kwibhokisi yokunciphisa isantya segesi ingaphantsi kwe-5000Hr, ngoko kufuneka utshintshe; igrisi idibanisa kanye ngeveki.

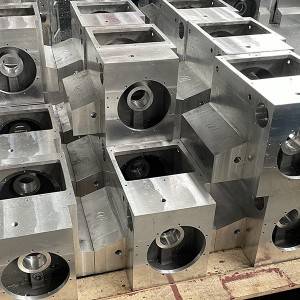

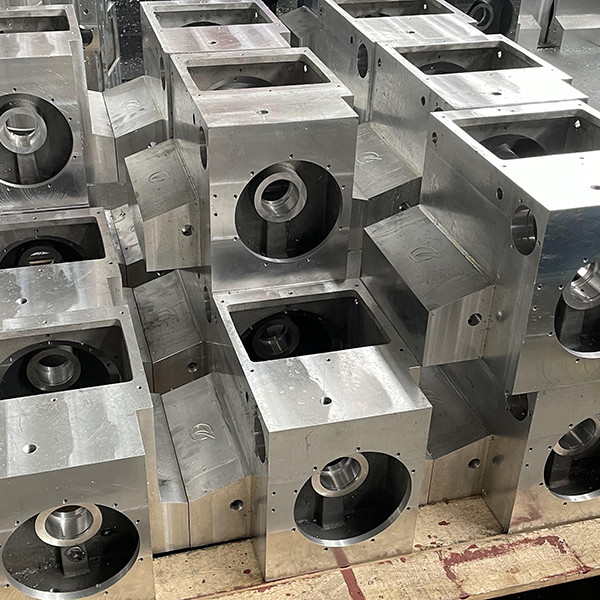

SS Umbhobho Mill Mold

I-mold yethu ithatha inkqubo ye-CNC, inkqubo yokuchaneka okuphezulu Ukusetyenziswa kwezinto eziphathekayo i-Cr12mov, i-SKD11, i-D2, emva konyango olukhethekileyo lokushisa, ubunzima ukuya kwi-61-63HRC Ukuveliswa kombhobho ojikelezayo, Ukujikeleza ngaphakathi kwe-0.05mm; Ukuveliswa kombhobho wesikwere, i-angle ye-flat surface ebukhali, emva kokupholisa, umphezulu unokuba sisibuko.

KubaSutyaniuMshini Wokwenza uMbhobho ongaphantsi kwentsimbiUkugcinwa koomatshini kunye nokusebenza:

a. Nceda ungabeki izixhobo, izikrufu, njl.njl kwizixhobo zombane, ezinjengeempompo, ukunqanda ukothuka kombane.

b. Akuvumelekanga ngokungqongqo ukungena kwisixhobo sofakelo kunye nokugcinwa, okanye ukubeka isandla sakho phakathi kwee-roller ezithe nkqo okanye ezithe tye ukutsala izinto ngelixa izixhobo zisebenza.

c. Emva kokukhanyisa izixhobo, jonga ngononophelo ukuba i-motor, i-reducer, i-gearbox, iirola ezithe nkqo nezithe tyaba zisebenza ngokuqhelekileyo ngaphandle kwesandi esingaqhelekanga kunye nokungcangcazela.

d. Kufuneka kubekho ukufikelela okwaneleyo kunye nokukhanya okujikeleze inkqubo yokusebenza ngokukhuselekileyo kunye nokugcinwa.

e. Xa usenza i-welding debugging, umsebenzi uya kunxiba iiglavu ezikhusela ubushushu kunye nezibuko.

f. Gcina izixhobo zicocekile.

g. Nika umoya owaneleyo apho kuyimfuneko.

h. Qinisekisa iindlela ezicacileyo kunye nokukhanya okwaneleyo.